Are Brake Cables and Shifter Cables the Same?

When you’re looking to outfit your bike with some new cables, it can be confusing to know which ones you need. The cables you’re looking for depending on the cables that came on your bike when you purchased it.

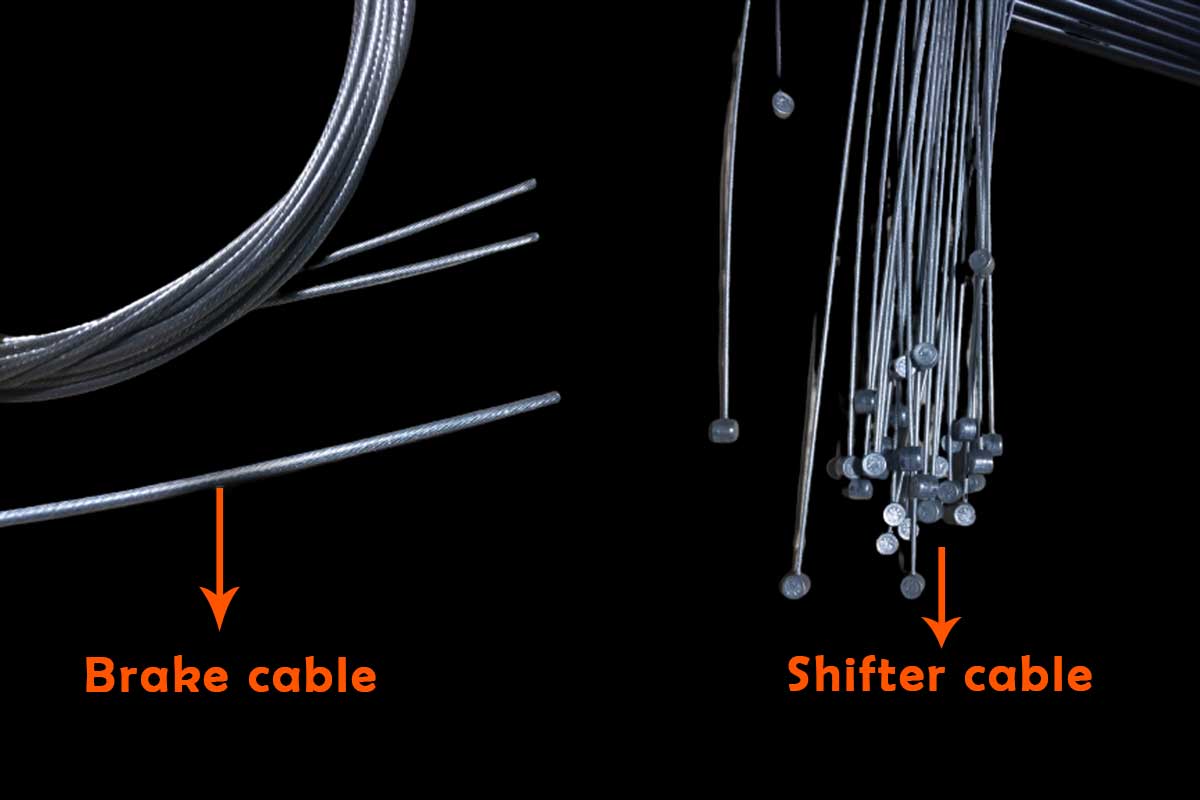

A question that’s arisen is whether these two different types of bike cable have identical construction or if there is something that separates them. Brake and shift cables are similar but not identical. Brake cables have a crimped section in the middle of the housing, while shifter cables don’t.

This article will explain all the relevant things you need to know about these two parts. Also, I’d give you more information on each type of cable and what you need to know when buying brake and shift cables. So, read on!

The Evolution of the Brake cables

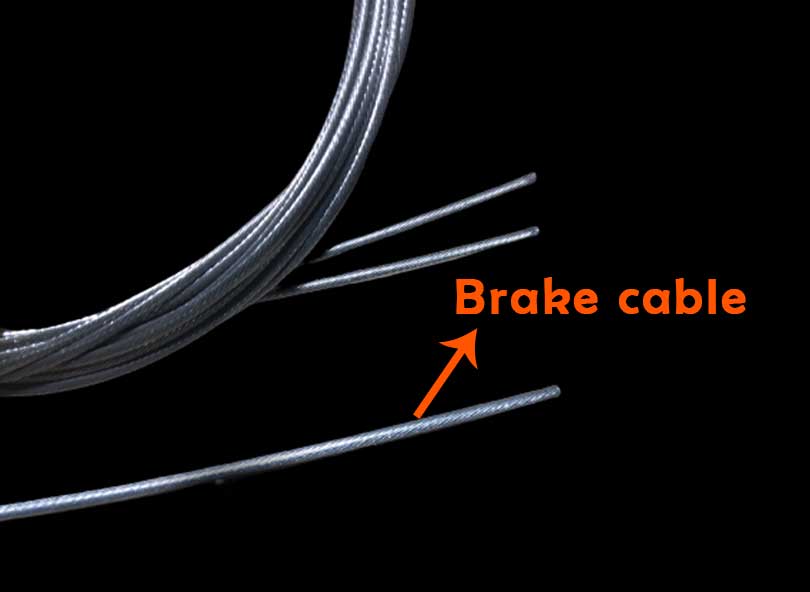

Brake cables are essential and most of the time overlooked components in your braking systems. It helps ensure you can stop your motorcycle, bicycle, or car at any given moment when brake cable issues. It can turn deadly in a hurry when they start to wear down. Most cable systems are composed of both an inner and outer cable, with a sheath holding the two together. The inner cable is steel wire, the sheath is usually made from a synthetic plastic.

The most important part of a brake cable is the outer cable housing. It usually consists of a thin steel tube that surrounds the inner cable. The housing is attached to most brake assemblies with a crimp, clamp, or clip. The tube has grooves at regular intervals to expand or contract as needed when braking.

These cables are usually made from an inner and outer wire attached to a sleeve over. The inner wire keeps it from fraying when exposed to external elements and wear and tear. If the sleeve is removed, you should lubricate the inner wire before re-inserting it into its sleeve.

It should be lubricated regularly, especially if you live in a dry climate. If the wire is allowed to rust, the sheath may twist around the inner cable. It can cause friction and rattle as you ride. Cable ends are vital points to check before riding or driving. Any corrosion or fraying should be fixed before your next ride or drive.

Brake Cable Performance: How Do Brake Cables Work?

Brakes are usually made up of many different parts and systems. This system handles transmitting pressure from the brake lever to the calipers and then onto the rotors. These cables are generally made of steel cables with an inner lining of high-grade, oil-resistant rubber.

This construction is necessary because they must transmit extreme amounts of pressure. But they also must be flexible enough to let you apply pressure on a brake at different angles. It might seem like a simple task, but it isn’t very easy by all the different parts that allow it to stop your car so effectively.

The braking force transmission is a crucial part that makes a good system work. Brake cables transmit the pressure from the brake lever to the calipers. As a result, they are lined with the toughest and most advanced material available: synthetic rubber. This material, like all rubber, has characteristics that make it the best fit for a functioning brake cable.

The Evolution of the Shifter Cables

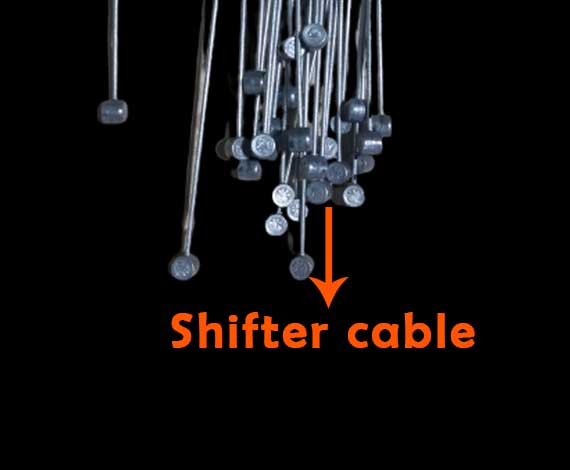

Shifter cables are a type of cable that can change length. It provides an alternate route for connecting two machines that are too far apart to form a straight line. It allows you to use the cable as a temporary shortcut or avoid disasters like tripping over long cables on a conveyor belt. A common design of shifter cable is used in robotics and machine tools applications. The most common type of shifter cable is a Bowden cable, named for its inventor, Frank Bowden. The design uses a self-contained chamber to keep the inner, movable portion of the cable from bending.

These cables can enable communication between two computers that are too far apart to form a straight line. For example, they can use a local area network (LAN) instead of a local area network. They can be useful if you need to connect computers to remote locations. As like monitoring the temperature on a factory floor or using an industrial robot across the room. The cable is also useful when an obstacle blocks the straight path between the two machines, such as a conveyor belt.

The cable starts with a flexible, cable body. It is located by two sheaths of rigid gripping material on either end of the cable. The gripping material clamps down on the flexible body to keep it in place. The inner cable portion can move along the length of the cable to change its length and configuration. It can travel in a straight line when the cable is not bent, or it can turn. It allows you to avoid obstacles, or reverse direction if needed.

Shifter Cable Performance: How Do Shifter Cables Work?

A shifter cable is a vital part of any automobile transmission. It connects the gear shift lever in the car’s cabin with the transmission and gives the operator a smooth, fluid motion from forward to reverse and vice versa. But how does it work?

These cables are usually made from steel and rubber, depending on their intended use. Steel provides durability while rubber provides flexibility and helps any shocks a cable might be subjected to. The length of each cable is important as well. They need to be long enough to reach all the components in the transmission but not so long that they don’t provide good tension between the two ends. If a shifter cable is too short, it will bind up or prohibit shifting completely.

Shifter cables must stretch and contract with equal strength to provide a smooth, seamless motion. If one side of a cable is not as strong or flexible as the other, it will allow the gears and transmission to shift poorly or even improperly. There are at least three shifter cables in any transmission setup: one for reverse, one for first gear, and another for second gear.

When you shift gears, these cables move up or down through the holes in the transmission tunnel (center console) to change gear ratios within the transmission. As they move, there are internal gears within the cable’s casing that switch position. One set of gears is attached to each side of another set of gears attached to another pair of gears, etc. The gears are arranged in the sequence the transmission needs to shift properly.

The gears and the cable’s moving parts switch positions within the casing so that they engage and disengage in a predetermined order. They move back and forth until it is time for another gear change, then they stop. Each of these steps happens hundreds of times each minute, so you don’t have to push very hard on the shift lever to get your car into gear. It all happens smoothly and automatically while you do something else.

Benefits of using a brake cable over a shifter cable

Many cars are fitted with a shifter cable which is often identified by the split clamps on the either brake disc. The brake cable works similarly to the shifter cable. It moves in an up-and-down motion when the brakes are depressed. Brake cables stop cars from moving, whereas shifter cables have the opposite effect and allow movement.

The benefits of using a brake cable over a shifter cable are numerous. The most obvious is the cost. Shifter cables require more precision and quality to function properly, whereas brake cables do not require such attention.

Brake cables are also much safer than shifter cables. If a cable breaks or shreds, it doesn’t allow the vehicle to move backward or forwards. When a car is shifted into reverse and the push-back mechanism isn’t working properly, this leaves the driver without stability in case of an accident or sudden stop. Here are the benefits of using a brake cable over a shifter cable:

- The brake cables are easier to adjust and replace.

- Brake cables can replace without replacing all of your steering system and steering wheel, unlike bulky shifter cables.

- The cost of a brake cable is much cheaper than a shifter cable.

- Brake cables are less likely to fail because of the simpler mechanics involved in their functionality.

- It’s cheaper and easier to replace your brake cable than a shifter cable and it doesn’t take long at all to do it yourself.

- Brake cables are much easier to maintain and use.

- It can be fitted to different cars depending on their needs, whereas shifter cables are a permanent part of each car’s specifications.

- Brake cables are safer because they work as a brake pedal to stop the car, whereas shifter cables allow motion.

- These cables are more cost-effective and their installation is simpler than that of a shifter cable, which requires more money and time.

Are Brake Cables and Shifter Cables the Same?

The main purpose of a brake cable is to stop your bicycle. When you squeeze the lever on your handlebars, it activates the brake pads and stops your bike. Brake cables are made of steel, rubber, or Kevlar, and are connected to levers on your handlebars through a cable housing. Brake cables also come with a small piece meant to stop crimping in the event of any stress or strain on the cable.

Shifter cables connect to the levers on your handlebars and control which gears you use, making shifting under your saddle possible. Shifter cables are made from steel and sometimes Kevlar, as well. Their main purpose is to enhance the performance of your bicycle by controlling the gears under your saddle.

Both brake cables and shifter cables are important parts of your bicycle. While they may not seem like the same thing, these two aspects are integral for your bike’s safety and performance. Here’s what you need to know.

Brake Cables Vs. Shifter Cables

The brake cables of your bicycle are connected to the brake levers on the handlebars, which control the brake pads below your bike wheels. The shifter cables of your bicycle are connected to the shifters on your handlebars that control the gears and shift under your saddle. If you are looking for high-quality and reasonably priced new or replacement brake or shifter cables for your bike. In that case, Bikecablepro has a wide selection of top-quality options that will fit any bike make and model. Now, I look at some similar parts but differ in use and purpose.

Similarities Between Brake and Shifter Cables

If you’re not sure what cables are – they are the large rubber tubes that operate your brakes and shifters. It is a very basic definition, but it’s a great place to start.

Both brake and shifter cables operate your brakes and shifters. In other words, they are part of the braking system in both applications on your bike. A good rule of thumb is that if you have both brake and shifter cables, check them for any fraying or cracks. Both cables are also

susceptible to rust, especially if they are not oiled regularly.

Although it’s easy to forget about cables, they are crucial for your bike. Luckily for you, their typical lifespan is about 100,000 miles. As if that wasn’t good enough news already – most bike shops will replace brake and shifter cables for free.

Differences Between Brake and Shifter Cables

The main difference between brake and shifter cables is the handlebar lever and the shifting mechanism they control. Brake cables control the brake lever, which you pull to stop the bike. Shifter cables control the shifter lever, which you push or pull to shift gears up or down.

Shifter cables also have another function that brake cables do not: They hold your handlebar’s position once you set them there. Brake cables do not have this function because their only job is to activate the brakes when you squeeze the lever.

If you’re looking for a replacement for your brake cable and shifter cable, it may be good to replace both at once if they are not compatible. While some bikes may have separate brake and shift cables, many modern bikes have combined brake and shifter cables.

Conclusion

The key difference between brake and shifter cables is that brake cables are thicker. The thickness of a wire is measured by the number of copper wires it contains. Brake cables have three copper wires to make them thick enough to contain all the heat generated by stopping your car. Shifter cables don’t need to be as thick, so they only have one wire, and they’re not as heat resistive because there’s less copper inside.