How long do aluminum bike frames last?

Many people ask themselves, “how long do aluminum bike frames last?” by purchasing a bicycle made of aluminum. Many consumers have found that their bikes can last up to ten years or more. This means that they are getting a great return on their investment because of the value they get with their bike. However, there are some downsides to this product. Aluminum bike frames corrode and rust over time, making the product less attractive and dangerous when it’s wet outside or in pools. The more corrosion on the bike, the more likely it will break, which can cause injury to the rider. However, some manufacturers have found a way to protect against this corrosion and rust using coatings and paints on their bikes.

What are the most common aluminum alloys used for bike frames?

The most common aluminum alloys for bike frames are 6005, 6061, 7000 series, 7075, 8219 Al/5052 Al/5083 Al/6086 Al. The most commonly used aluminum alloy for bike frames is a trade secret. The different types of aluminum alloys are usually only disclosed to those who must know for quality control.

6005 – The most common alloy used in bicycle frames because of its strength, ductility, and weldability. It is typically formed into thin-walled tubing with rounded profiles. It has optimal properties in tempering and annealing, as well as good forming characteristics. It is increased strength, a high strength-to-weight ratio, and low cost compared to 7075 and 7050.

6061 – This alloy is highly resistant to heat treatment and cold formability. It is used in frames to allow for thinner wall thicknesses. Its lower strength when compared to 6075 means it can be saved weight, with the added benefit of more compliant ride quality.

7005 – The 7005 alloy has improved properties than the commonly used 7075 alloy. It is a strong alloy with good corrosion resistance and toughness. It is highly resistant to impact, abrasion, and stress cracking.

7075 – This alloy is among the strongest alloys used in bicycle frames. It does, however, have poor formability and weldability. Since most bike frames are formed into thin-walled parts, the alloy may be better suited for thicker tubes or bars (seat stays, chain stays, or dropouts).

7050 – This alloy has excellent formability, weldability, and high corrosion resistance. It is the best choice for all-weather bicycle frames, but it is not commonly used. This may be because it contains a small amount of lead to improve its forming quality, which makes it hazardous during welding.

8219 Al/5052 Al/5083 Al/6086 Al – These are some rarer aluminum alloys used in bike frames. They are typically used in dropouts, chain stays, and seat stays. They have a low carbon content, so they are resistant to corrosion, especially in saltwater environments. The high nickel content further improves its corrosion resistance.

How long do aluminum bike frames last?

There is a lot of confusion about how long aluminum bike frames last. An aluminum frame does not mean it will last for life. Aluminum frames carry a lifetime warranty on all components, but the odds are that after years of riding and hundreds of miles, you will encounter some problems.

It’s important to keep everything in perspective when talking about any product’s life expectancy or durability. For aluminum frame- its durability depends on the following:

Quality and construction: The aluminum grade used to build this frame and how finely the construction process is completed are the main factor for the lifespan of the aluminum bike frame.

Style of riding: Rider’s riding style will also affect the lifespan of the aluminum bike frame.

Riding frequency: How frequently is the bike ride? The more the bike is ridden, the less the bike’s lifespan.

Rider Weight: Rider’s weight is also important for aluminum bike frames’ lifespan. Cause the more the rider’s weight, the more stress the bike frame will get while riding.

However, A well-made product that is taken care of should last 20 years or better with low chances of breaking down early due to normal wear and tear.

A quality aluminum frame bike should be good for at least 10,000 miles but will most likely last much longer. So, if you ride an average of 3 miles daily, it will take ten years to complete 10,000 miles.

Metal frames need to be cared for routinely and maintained; without proper care, they can rust and deteriorate quickly. It is important to remember that anything made out of metal is a good conductor of electricity. So, it is important to take precautions when storing, charging, or using a metal frame bike as an e-bike.

Please note that aluminum bike frames can rust and deteriorate just as quickly as steel or titanium bike frames, but with proper care, the longevity of an aluminum frame bike is much longer.

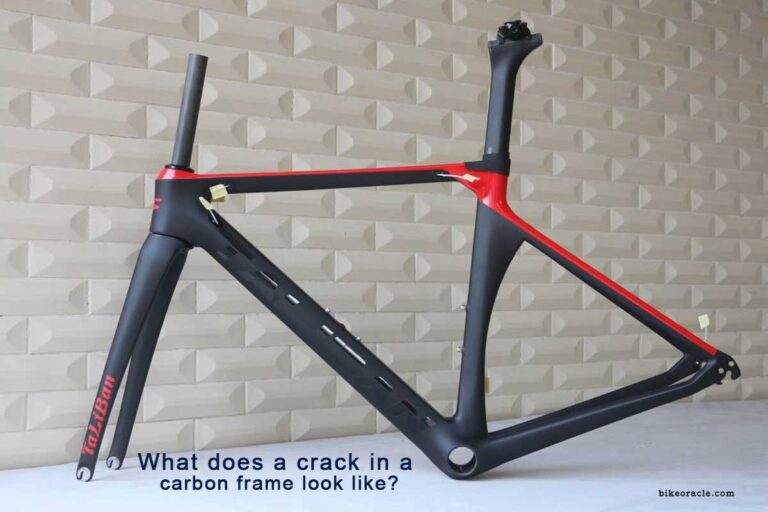

Do Aluminum Bike Frames Crack?

One of the most common questions is, “will an aluminum frame crack”? That’s a difficult question because it takes a lot of bike riding before an aluminum frame shows signs of wear. Aluminum frames do not rust or corrode, so you don’t need to worry about them getting gritty and nasty, but they have their downsides.

Aluminum isn’t as stiff and strong as steel, so it doesn’t absorb bumps as well. This makes for a more comfortable ride, but it might not be as high-end as a steel frame. Aluminum also can’t take the same amount of punishment that a steel frame can. It’s more prone to bending and denting at high speeds or crashes.

Aluminum is a relatively soft metal, so aluminum bike frames are often susceptible to cracking when bent or compressed in an uncontrolled or unexpected way. If your bike falls over while riding it and lands on the top tube, for instance, there’s a good chance that your frame will experience deformation. This compression type happens to most aluminum frames at some point and requires a relatively simple repair.

Aluminum frames also crack when subjected to large amounts of stress in a controlled way. This is more common than you might think and occurs in several different ways.

At what places do aluminum frames crack most frequently?

Aluminum is a very durable material, but it won’t be able to withstand stresses on its frame from impact or high-stress loads without cracking. Some patterns, however, are known to be more susceptible to cracks in aluminum.

This is a common question that people always ask. Most people assume that cracks occur when in a crash or during a high-impact event. However, these fractures are not caused by these types of accidents. Cracks in aluminum are caused by impacts, overstraining, or chemical reactions between aluminum and other substances.

The most common places where frames crack is at joints where they join the front fork with the front end and the head tube assembly to the frame’s top tube. The most common cracks you may see are at the frame’s head tube, front fork, and down tube.

The front fork to top tube joint is an area that is often tested by riders when they have to have their fork replaced. Typically, the right side of the frame will crack first, and the left side will crack last. Once a small crack has occurred in one place, it’s not uncommon for that section to be weakened and caused to fail after a short time.

The rider will also notice that the frame has bent at the joint between the fork and the front end. The front fork to top tube joint is where a lot of stress is put on a bike frame; this is why it appears on the list of most common places for aluminum frames to crack.

The head tube to the bottom bracket area is another area susceptible to cracks. It only takes a small crack in the aluminum (typically around 2mm) before it’s weakened and causes the entire top tube to fail. The rider can notice this by the top tube flexing or having a clear crack in the frame.

Cracks in the seat tube or near it are also common. This is because the seat post puts Pressure on the area, and cracks can be caused by normal riding. You might also even think that your bike frame is fake if you see cracks in any of these areas, but it’s not uncommon for aluminum frames to crack in these areas.

Another place where aluminum frames often develop cracks is at welds. It is not uncommon to see welds develop cracks in aluminum frames. This can be because of welding parameters or even repairs done improperly by the welding company that repaired them.

Aluminum is very difficult to weld, which is why it’s so common to see cracks in welded aluminum frames. It is also common to see welding with argon gas due to the exothermic properties of the gas. Welding with the gas will increase the temperature and hence the amount of weld cracking.

What Causes Cracks in Aluminum Bicycles?

If you have an aluminum bicycle, you might want to look at the spokes and the frame for signs of corrosion. The propagation of cracking can lead to bent or broken frames, and as such, these signs should be noted by cyclists. Signs of corrosion on aluminum bike frames include: appearing rough or pitted in places where light doesn’t penetrate; exposed metal; shiny surfaces with lumps or bumps; oxidation that looks like swampy dirt on the bicycle’s paint job.

The cause of cracking on aluminum bike frames is oxidation and its effects on the bikes. Various factors can cause oxidation:

— Excessive heat or cold – when bicycle frames are exposed to extreme temperatures, they sometimes crack due to corrosion. This may be because of the metal’s high susceptibility to heat and cold or because conditions such as salt spray or vibration can cause cracks.

— Serious crashes — In accidents that can significantly impact aluminum bikes are more susceptible to cracking. This may be because of the force intensity in these incidents or because they are not designed to handle such forces.

— Exposure to liquids – For bikes exposed to liquid, the metal might have weakened.

— Pressure applied on the frame for weapons or other objects – Certain objects can cause damage to a bicycle, such as certain weapon mounts.

Large aluminum bicycle frame weights can sometimes break the crank arms. A broken crank arm can result in a frame crack. Frame Flexing Can Also Cause Cracks if Not Properly Stretched During Fabrication. Most bicycles include rubber pads on their bottom bracket and headset bearings to ensure that these parts don’t flex as much as expected for their size and weight. Cracks can sometimes form if the bike frame flexes too much in any direction.

To find out if your bike is prone to cracking and how it can be prevented from happening, contact a bicycle repair store or get advice from someone with experience in this field.

How To Repair Aluminum Bike Frames?

Aluminum bikes are extremely durable, making them perfect for riders looking for a good, long lifespan from their purchase. However, even aluminum frames need to be repaired from time to time. Here are some ways to do so.

Cycling shoes and pedals: If you experience pedal or shoe problems, these are easy fixes requiring little or no work. Remove the pedals and wings, and apply cyano grease to ensure that they spin smoothly when you put them back on.

Cracked handlebar: Many cyclists keep their handlebars cracked due to several possible causes. Cracks on your aluminum bike frame can be serious and should be fixed immediately. The best way to handle this is to use an epoxy solution, which will fill in the cracks without affecting performance or strength.

Bent Bolts: Bent bolts are a common problem on aluminum bike frames, but most problems can easily be fixed at home. If a bolt is bent out of shape, place the tool into a drill press and carefully run it over the affected area until it straightens itself out. If you’re unsure about this, consult a professional for tips.

Bent fasteners: Bent fasteners can cause many problems with your aluminum bike frame. If a bolt or screw is bent out of shape, place it back in the original position, then put a crack in the bolt or screw. Cover the crack with an epoxy that matches the color of your bike frame, and allow it to dry for 24 hours before riding.

Polish coating: If your aluminum bike frame has a glossy paint job, use any aluminum polish paste to buff out any scratches. This will restore your frame to its former glory without repainting it.

Small scratches: If you have a small scratch on your roughed-up bike frame that is too deep for a polish job, consider using some fine grit sandpaper. Sand the area carefully until it’s smooth and shiny again, then apply some polish to prevent further scratching.

Road rash: If you have road rash on your bike frame due to poorly used brakes, it may be time to call in an expert. Some bicycle frames are made of aluminum and can easily be damaged by the wrong braking mechanism.

Frame stripping: You can remove the finish from your frame at home by carefully sanding the paint off with fine grit sandpaper, then reapplying it to restore its original appearance. Be careful not to leave scratches on the frame after stripping, as these will weaken it and make it less sturdy over time.

How can the life of an aluminum frame be extended?

The life of a frame can be extended by ensuring it remains in good condition. Below are four tips that will help you to achieve this:

1) Keep your bicycle as intended: Be mindful when jumping curbs, off curbs, and using ramps or stairs to avoid damage to the frame. Aluminum frames are designed for light use and should not be overworked or ridden off-road or in heavy weather conditions.

2) Clean the bike regularly: remove grit from the chain, cassette, and derailleur with a clean cloth and brush. Also, clean the frame and wheels with a bicycle-specific cleaner.

3) Use frame protection: Ensure the frame is protected from excessive bumps and environmental scrapes. Regularly check the frame’s condition to reduce the possibility of rust and ensure your bicycle is in good working condition.

4) Regular inspection of your bike: Check that all bolts are tight, check for cracks or discolors in paintwork, and check the cables are well lubricated and undamaged

Is it wise to buy a second-hand aluminum frame?

Many people are tempted to buy second-hand aluminum frames to save some money. If you’re among them, here’s a discussion on whether this is worth doing or not.

As you may already know, aluminum frames are known for their long-lasting quality and solid construction. This makes them a good investment, as you won’t need to spend money replacing them for years. Even so, when it’s time to replace the fork and components of the bike, you’ll have to spend a lot of cash on new ones.

An aluminum frame is already more affordable than most high-end carbon fiber models. However, buying a used one will only make it even cheaper. This could compel you to buy something that may not be in its best condition now. Do you want to spend a lot of money on something that may not be high quality?

In addition, some sellers are known to stretch out the truth about the condition of their bikes. They do this to make their products look more attractive in their posts. Some even go as far as to remove evidence that proves their product is second-hand.

You might end up buying an aluminum bike with a frame that’s been damaged in an accident or has been severely worn out through constant use. If that happens, you need to know that most manufacturers cannot repair it for you. They will tell you to buy a new one instead.

If the seller is kind enough to let you check on the condition of the frame and components before purchasing one, go ahead. If not, it’s better not to buy something they won’t allow you to check out beforehand.

Besides, buying a used aluminum frame might put you off or make you feel bad. If you’re feeling bad, leaving such a bike alone is best.

Why are aluminum bike frames cheaper than steel?

Aluminum bike frames are cheaper than steel because aluminum can be created more cheaply and easily than steel. Aluminum has a higher melting point than steel, which makes it less susceptible to corrosion and cracking as might be induced by repeated Exposure to water or salt. Specifically, the trend in consumer preference over the past decade has been toward lightweight aluminum frames instead of heavier steel ones.

The trend toward aluminum frames has largely been driven by consumer preference. Both materials are technically viable, and neither offers a clear style or performance advantage to the consumer or the manufacturer. There is no technological reason why bikes should be constructed out of one material over another. Quite simply, aluminum is cheaper to produce, which makes it cheaper to buy, and that is the fundamental difference between steel and aluminum frames in modern bicycles.

Conclusion

In conclusion, whether it is the frame, fork, or even components that are aluminum, they should last for a long period of time. The only parts that would be subject to wear and tear are the tires, which are easily replaced with new ones. An aluminum bike frame can last up to 8 years when used in proper conditions. Not bad at all! The durability of an aluminum bike frame is just another reason why aluminum is the material of choice for its weight and strength. A nine-year-old bike is still going strong after nearly a decade of regular use because it was made from an alloy that is durable.

I hope this article has provided you with information regarding the long-lasting nature of aluminum and how it is used in the production of many bike frames. Happy riding!

![What Oil Can You Use On a Bike Chain – [Answered]](https://bikeoracle.com/wp-content/uploads/2023/08/What-Oil-Can-You-Use-On-a-Bike-Chain-768x512.png)