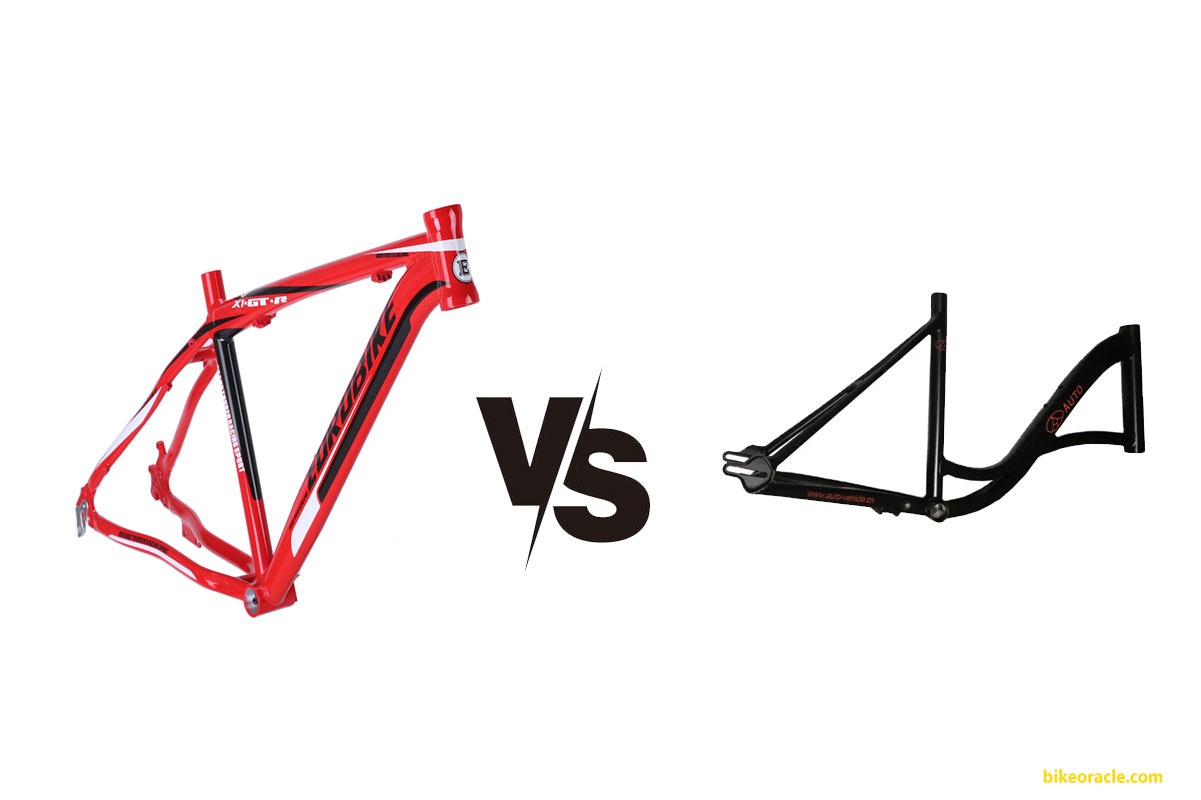

6061 vs 7075 aluminum bike frame – What’s The Difference?

The choice of bike frame material significantly impacts performance and ride quality. The casing is the foundation of a bicycle, giving steadiness and primary trustworthiness. Aluminum has arisen as a well known material because of its lightweight and vigorous properties. In this article, we center around the discussion between two broadly utilized aluminum combinations: 6061 and 7075.

Understanding their differences is crucial for making an informed decision when choosing a frame. The cycling community has been captivated by the discussion surrounding 6061 and 7075 aluminum frames. Both alloys offer unique advantages. While 6061 is known for versatility and cost-effectiveness, 7075 boasts superior strength and rigidity.

In this comprehensive guide, we explore the distinctions between 6061 and 7075 aluminum frames. We analyze key factors like strength, stiffness, weight, corrosion resistance, durability, manufacturing processes, and cost. By providing valuable insights, we aim to help riders make an informed choice.

Let’s delve into the world of 6061 and 7075 aluminum frames to uncover the differences that shape the cycling experience!

Understanding Aluminum Bike Frames

The popularity of Aluminum: Lightweight and Durable

Aluminum bicycle outlines have acquired monstrous ubiquity because of their lightweight and tough nature. Aluminum is known for its brilliant solidarity-to-weight proportion, making it an optimal material for building bicycle outlines.

Its low thickness considers simple mobility and deft dealing with different landscapes. Also, aluminum outlines display high protection from consumption, guaranteeing enduring execution and solidness, even in unforgiving atmospheric conditions.

Advantages of Aluminum Frames over Other Materials

Compared to other frame materials, aluminum offers several advantages. Firstly, aluminum frames are more affordable, making them accessible to a wide range of riders. Secondly, aluminum’s stiffness enhances power transfer, resulting in efficient pedaling and improved acceleration. Furthermore, aluminum frames can be designed with intricate shapes, enabling manufacturers to optimize frame geometry for specific riding styles and preferences.

Role of Frame Material in Ride Quality and Performance

The choice of frame material significantly impacts ride quality and performance. Aluminum frames provide a responsive and lively ride, thanks to their stiffness and excellent power transfer. This translates to efficient energy transfer from the rider to the bike, resulting in better acceleration and control. Additionally, the lightweight nature of aluminum frames contributes to agility and nimbleness, allowing riders to navigate tight corners and technical sections with ease. The choice of an aluminum frame can greatly enhance the overall riding experience.

Exploring 6061 Aluminum Frames

Overview of 6061 Aluminum Alloy

6061 aluminum compound is a generally involved material in the development of bicycle outlines because of its positive properties. It has a place with the 6xxx series of aluminum compounds, which are known for their fantastic solidarity-to-weight proportion. The compound comprises aluminum, magnesium, and silicon, giving a decent equilibrium of solidarity, strength, and erosion obstruction.

Characteristics and Properties of 6061 Aluminum

6061 aluminum exhibits several key characteristics that make it suitable for bike frames. It has a high tensile strength, allowing it to withstand rigorous riding conditions. The alloy also offers good fatigue strength, which is important for prolonged use. Additionally, it has a favorable stiffness-to-weight ratio, contributing to efficient power transfer and responsive handling.

Strengths and Weaknesses of 6061 Aluminum Frames

Strengths:

- Lightweight: 6061 aluminum frames are relatively lightweight, making them ideal for riders who prioritize agility and maneuverability.

- Affordable: Compared to some high-end aluminum alloys, 6061 aluminum frames are generally more budget-friendly.

- Versatile: 6061 aluminum is highly versatile, allowing for various frame geometries and designs to cater to different riding styles and preferences.

Weaknesses:

- Lower Strength compared to some other aluminum alloys: While 6061 aluminum offers good strength, it may not be as strong as certain high-end alloys like 7075.

- Less Stiffness: Compared to stiffer alloys, 6061 aluminum frames may exhibit slightly more flex, which can affect overall responsiveness and precision in handling.

- It’s important to note that despite these limitations, 6061 aluminum frames remain popular and suitable for a wide range of riders, especially those seeking a balance between performance and affordability.

Delving into 7075 Aluminum Frames

Overview of 7075 Aluminum Alloy

7075 aluminum is a high-strength compound known for its remarkable mechanical properties, going with it a famous decision for requesting applications, including aviation and sporting gear. It has a place with the 7000 series of aluminum composites, which are fundamentally made out of zinc as the principal alloying component. This combination is explicitly intended to offer unrivaled strength while keeping a moderately low weight.

Characteristics and Properties of 7075 Aluminum

7075 aluminum displays a phenomenal solidarity-to-weight proportion, making it one of the most grounded aluminum amalgams that anyone could hope to find for bicycle outlines. It has an elasticity of around 83,000 psi and a yield strength of roughly 73,000 psi.

This high strength enables the frame to withstand rigorous riding conditions, including rough terrains and aggressive trails. Additionally, 7075 aluminum offers good fatigue resistance, ensuring long-lasting performance.

Strengths and Weaknesses of 7075 Aluminum Frames

Strengths:

- Exceptional Strength: 7075 aluminum frames provide an excellent strength-to-weight ratio, offering superior durability and reliability.

- Rigidity: The high-strength properties of 7075 aluminum contribute to a rigid frame, enhancing stability and control during aggressive riding.

- Stiffness: The alloy’s stiffness helps transfer power efficiently, resulting in responsive acceleration and improved handling.

Weaknesses:

- Limited Flexibility: Due to its inherent stiffness, 7075 aluminum frames may have limited compliance, potentially leading to a slightly harsher ride on rough terrains.

- Cost: 7075 aluminum is generally more expensive compared to other aluminum alloys, which can impact the overall cost of the bike.

7075 aluminum frames are favored by riders who prioritize strength and durability, especially in disciplines such as downhill racing and aggressive trail riding. The alloy’s exceptional mechanical properties provide riders with confidence and reliability on challenging terrains, ensuring optimal performance in demanding riding conditions.

6061 vs 7075 Aluminum – Strength and Stiffness Comparison

A. Evaluating the Tensile Strength of 6061 and 7075 Aluminum

6061 Aluminum:

- Tensile Strength: Around 40,000 psi (pounds per square inch)

- High tensile strength provides good durability and resistance to deformation.

- Suitable for a wide range of applications, including frames for mountain bikes, road bikes, and recreational bikes.

- Offers an excellent strength-to-weight ratio, allowing for lightweight frames without sacrificing durability.

7075 Aluminum:

- Tensile Strength: Approximately 83,000 psi

- Significantly higher tensile strength compared to 6061 aluminum.

- Exceptional strength properties make it ideal for demanding applications, such as aerospace components and high-performance bike frames.

- Provides enhanced resistance to fatigue, ensuring long-lasting performance under extreme conditions.

B. Understanding the Stiffness of Each Aluminum Alloy

6061 Aluminum:

- Modulus of Elasticity: Approximately 10 million psi

- Offers a balanced level of stiffness, providing a comfortable ride with good responsiveness.

- Absorbs vibrations effectively, contributing to a smoother riding experience.

- Allows for efficient power transfer from the rider’s pedal stroke to the wheels.

7075 Aluminum:

- Modulus of Elasticity: Approximately 10.2 million psi

- Exhibits a higher level of stiffness compared to 6061 aluminum.

- Offers enhanced responsiveness and precise handling, making it suitable for riders seeking optimal control.

- Transmits power efficiently, allowing for quick acceleration and sharp cornering.

C. Impact on Ride Quality and Handling

6061 Aluminum:

- Provides a comfortable ride due to its balanced stiffness and ability to absorb vibrations.

- Offers predictable handling characteristics, making it suitable for a wide range of riding styles and terrains.

- Well-suited for riders seeking a versatile frame with a combination of durability and comfort.

7075 Aluminum:

- Enhances overall ride quality by offering increased stiffness and responsiveness.

- Provides precise handling and improved control, making it ideal for riders who prioritize aggressive riding, such as downhill or enduro.

- Offers a more dynamic and lively feel, allowing riders to push their limits with confidence.

Understanding the differences in strength and stiffness between 6061 and 7075 aluminum is crucial in selecting the right frame for your riding needs. Consider your riding style, terrain preferences, and desired ride characteristics to make an informed decision that will enhance your overall biking experience.

6061 vs 7075 Aluminum – Weight Considerations

Weight Comparison: 6061 vs 7075 Aluminum Frames

When it comes to weight, there are slight differences between 6061 and 7075 aluminum frames. Overall, 6061 aluminum outlines will quite often be marginally lighter contrasted with 7075 aluminum outlines.

A run-of-the-mill 6061 aluminum outline weighs around 2.7 to 3.0 pounds (1.2 to 1.4 kilograms), while an equivalent 7075 aluminum outline weighs roughly 2.9 to 3.2 pounds (1.3 to 1.5 kilograms).

Effects of Frame Weight on Bike Performance

The heaviness of the edge assumes a critical part in bicycle execution, especially concerning speed increase, climbing, and mobility. A lighter casing can add to further developed speed increase and climbing capacities, permitting riders to handily vanquish steep slopes and speed up quicker on pads. It likewise improves mobility, making it more straightforward to explore sharp corners and curves. Notwithstanding, it’s essential to take note that edge weight is only one variable among numerous that add to general bicycle execution.

Balancing Weight and Durability for Different Riding Styles

Finding the right balance between weight and durability is essential, as it depends on the specific riding style and terrain preferences. For riders focused on speed, racing, or cross-country riding, a lighter frame like 6061 aluminum may be preferable to optimize performance.

On the other hand, riders who prioritize durability and strength for aggressive trail riding or downhill adventures may lean towards a slightly heavier but stronger frame like 7075 aluminum. It’s crucial to consider your riding style, terrain, and personal preferences to strike the right balance between weight and durability for an optimal riding experience.

Corrosion Resistance and Durability

1. Corrosion Resistance of 6061 and 7075 Aluminum

6061 aluminum frames offer good corrosion resistance, thanks to their alloy composition and the formation of a protective oxide layer. However, prolonged exposure to harsh environments, such as saltwater or acidic conditions, can still lead to corrosion over time.

On the other hand, 7075 aluminum frames have excellent corrosion resistance due to their higher zinc content. They can withstand more aggressive conditions without significant corrosion issues.

2. Factors Affecting Durability of Aluminum Frames

The durability of aluminum frames is influenced by several factors. The quality of the alloy, heat treatment, welding techniques, and overall frame construction play significant roles. Proper design, reinforcement, and support at stress points are crucial for long-term durability. Additionally, factors like rider weight, riding style, and maintenance practices also impact the lifespan of the frame.

3. Maintenance and Care Tips for Aluminum Frames

To maintain the durability of aluminum frames, regular cleaning is essential. Use mild detergents and water to remove dirt and grime. Avoid harsh chemicals that can damage the protective oxide layer. Inspect the frame for scratches, dents, or cracks regularly.

Apply touch-up paint to any exposed areas to prevent corrosion. Lubricate moving parts and ensure proper torque settings for bolts. Regular maintenance and care will help prolong the lifespan of your aluminum frame.

Manufacturing Process and Cost

Production Methods for 6061 and 7075 Aluminum Frames

Both 6061 and 7075 aluminum frames are typically manufactured using similar processes. This includes extrusion, where the aluminum is forced through a die to create the desired shape. After extrusion, frames undergo various machining and shaping processes, such as CNC milling and forming, to achieve the final design. These processes ensure precision and consistency in frame production.

Impact of Manufacturing Process on Frame Performance

The manufacturing process directly affects the performance characteristics of aluminum frames. Factors like tube shaping, butting, and heat treatment techniques determine frame strength, stiffness, and weight distribution.

Precise manufacturing ensures optimal frame performance, including efficient power transfer, vibration dampening, and overall ride quality. Attention to detail in the production process is crucial to achieving desired performance attributes.

Cost Comparison: Budget-Friendly Options and Premium Offerings

6061 aluminum frames are generally more cost-effective compared to 7075 aluminum frames. The lower cost is primarily due to the lower cost of raw materials and ease of manufacturing. This makes 6061 frames a popular choice for budget-friendly options and entry-level bikes.

On the other hand, 7075 frames tend to be more expensive due to the higher cost of the alloy and the additional manufacturing processes required for its production. These frames are often found on higher-end bikes that prioritize performance and durability.

Applications and Suitability

Recommended Applications for 6061 Aluminum Frames

6061 aluminum outlines are appropriate for many applications. They are usually utilized in off-road bicycles, street bicycles, worker bicycles, and sporting bicycles. Their mix of lightweight, solidness, and cost-adequacy makes them flexible for different riding styles and landscapes. 6061 frames excel in cross-country riding, general trail riding, and urban commuting, providing a balanced performance for a range of riders.

Optimal Use Cases for 7075 Aluminum Frames

7075 aluminum frames are typically found in high-performance mountain bikes, downhill bikes, and other demanding riding disciplines. The superior strength and rigidity of the 7075 alloy make it suitable for aggressive riding styles, including downhill racing and freeride. These frames excel in situations where durability, stiffness, and resistance to impacts are crucial.

Matching Frame Types to Riding Styles and Terrain

Choosing the right frame type depends on your riding style and the terrain you ride on. If you prioritize weight, cost-effectiveness, and versatility for a range of terrains, a 6061 aluminum frame is a solid choice.

For riders seeking maximum performance, and durability, and tackling demanding terrain, a 7075 aluminum frame offers superior strength and stiffness. Understanding your riding preferences and the intended use of your bike will help you make an informed decision when matching frame types to your riding style and terrain.

Customization and Frame Options

Availability of 6061 and 7075 Aluminum Frame Options

Both 6061 and 7075 aluminum frames are widely available in the market, catering to various riding needs and preferences. Many reputable bike manufacturers offer models with frames made from either alloy, providing riders with a range of choices.

Customization Possibilities for Different Riding Needs

Aluminum frames offer ample customization opportunities to tailor the bike to specific riding needs. Riders can explore options such as frame size, geometry adjustments, suspension preferences, and component compatibility. This flexibility allows riders to optimize their bikes for different terrains, riding styles, and personal preferences.

Considering Frame Geometry, Suspension Compatibility, and Features

When choosing an aluminum frame, it’s crucial to consider factors such as frame geometry, suspension compatibility, and desired features. Frame geometry affects handling characteristics, while suspension compatibility determines the type and travel of forks and rear shocks that can be used. Additionally, considering features like internal cable routing, mounting points, and tire clearance can enhance versatility and convenience.

Factors to Consider When Choosing

1. Riding Style: Determining the Right Frame Material

The choice between 6061 and 7075 aluminum frames depends on your riding style. If you prioritize lightweight efficiency and a balance between comfort and performance, 6061 aluminum frames are a suitable choice. On the other hand, if you require maximum strength and durability for aggressive riding or heavy-duty applications, 7075 aluminum frames excel in these areas.

2. Budget Constraints: Balancing Performance and Cost

Budget constraints play a significant role in frame selection. While 7075 aluminum frames tend to be more expensive due to their higher strength and advanced manufacturing processes, 6061 aluminum frames offer a cost-effective option without compromising on performance. It’s important to find the right balance between desired performance characteristics and available budget.

3. Longevity and Future Upgrades: Planning Ahead

Consider your long-term goals and potential future upgrades when selecting an aluminum frame. Both 6061 and 7075 aluminum frames provide durability, but 7075 frames offer higher strength and resistance to fatigue. If you plan to push your riding limits or anticipate future upgrades, investing in a 7075 frame may offer more longevity and versatility.

Maintenance and Care Guidelines

Cleaning and Protecting Aluminum Frames

Maintaining your aluminum frame involves regular cleaning to remove dirt, debris, and sweat. Use a mild detergent and non-abrasive cloth or sponge to clean the frame, avoiding harsh chemicals that can damage the finish. Applying protective coatings or waxes can help preserve the frame’s appearance and prevent corrosion.

Inspecting for Structural Integrity and Fatigue

Regularly inspecting your aluminum frame is essential to identify any signs of structural integrity issues or fatigue. Look for cracks, dents, or significant damage that may compromise the frame’s strength. Pay attention to stress points such as welds, head tube, and bottom bracket area. If you notice any abnormalities, consult a professional for assessment and potential repairs.

Repair and Replacement Options for Damaged Frames

In the unfortunate event of frame damage, repair or replacement options depend on the severity and location of the damage. Small scratches or paint chips can be addressed with touch-up paint, while significant structural damage may require professional repairs or, in extreme cases, frame replacement. Consult with a qualified bike shop or frame specialist for expert advice.

Conclusion

Choosing between 6061 vs 7075 aluminum bike frames involves considering factors such as riding style, budget, and long-term goals. Understanding the differences in strength, performance, and cost helps make an informed decision that aligns with your specific needs.

Personalization is key when selecting an aluminum frame. Consider customization possibilities, including frame options, geometry adjustments, and suspension compatibility, to tailor the bike to your riding preferences and requirements.

Regardless of which aluminum outline you pick, both 6061 and 7075 proposition advantages like lightweight development, strength, and adaptability. Via cautiously considering factors like riding style, financial plan, and upkeep needs, you can go with a choice that upgrades your riding experience and permits you to partake in the many advantages of aluminum outlines.

![How to sand a bike frame? [Step-by-Step Guide]](https://bikeoracle.com/wp-content/uploads/2022/11/How-to-sand-a-bike-frame-768x512.jpg)

![How much does it cost to paint a bike frame – [Answered]](https://bikeoracle.com/wp-content/uploads/2023/06/How-much-does-it-cost-to-paint-a-bike-frame-01-768x512.jpg)