How much does it cost to weld a cracked frame?

If you are someone who has made an effort to weld a cracked frame, then you know it can get pretty expensive. Some say that repairing yourself is worth it because of how much cheaper and more convenient it would be to replace the whole frame. However, welding is still an option if your frame is too damaged.

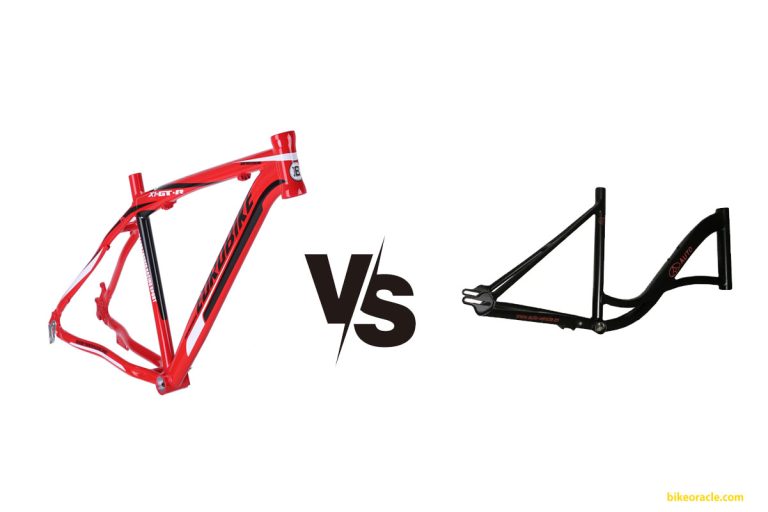

Different types of bike frames

1) steel frame:

A steel frame is a bicycle frame made from welded double-butted, heat-treated, chrome-molybdenum alloy steel tubing. They can be heavy and more rigid but offer solid performance and are generally reliable. Steel frames are usually painted or in a clear coat finish to prevent rusting.

2) alloy frame:

Alloy frames can be made of stainless steel, aluminum, or titanium. A frame made of an alloy (alternatively called a “metal matrix composite”) is the strongest and most durable but also the heaviest. A good example of an alloy bike frame is the Cannondale CAAD10 2010. Alloy frames are used in most competitive events. Alloy bikes can also be seen at BMX as well as Track races.

3) carbon frame:

Carbon fiber is a strong and extremely lightweight material, making them the most expensive bike frame type. Due to their very high cost, carbon fiber frames are mostly found in professional racing and sponsored events. However, the price of carbon frames has decreased, and they are more affordable than before. Carbon fiber is a very stiff material, making the ride fast and smooth. The ride is also comfortable because of its flexibility.

4) titanium frame:

A titanium frame is composed mostly of titanium but may also use some aluminum, copper, or steel. Titanium is an extremely strong, lightweight metal that tends to be expensive due to its rarity and difficulty in obtaining it in large sizes. Titanium is about 60% lighter than steel, making it flex less and easier to control. Due to its lightweight, titanium will “stiffen” when riding on rough terrain.

How are Cracked bike Frames Welded?

Cracked bike frames usually crack in a specific place. There are three main types of cracks:

1) The top tube occurs when the rider’s weight flexes down the bike frame and the steel snaps.

2) A side-to-side crack occurs when a weld fails due to poor material knowledge and process or fatigue.

3) Cracked frames occur when the frame is cracked during the welding process, either due to poor welding techniques and processes or improper material thicknesses.

These are the most commonly seen defects in bicycle frames. The process of welding a cracked bike frame is different for types of frames:

a)How are Cracked steel bike Frames Welded?

When it comes time to make your steel cracked frame welds, the old saying “practice makes perfect” quickly applies. The welders at Steel Cracked Bikes take their time and make sure that each weld is precise and consistent. This process begins with precision tools to ensure that all measurements are correct. Measurements are then used to create a blueprint to guide the process and produce the desired results. The next step is the cleaning and prepping your frame using grinders suitable for steel. Once everything is clean, they place the frame in a jig which helps to hold it in place as they work on it.

Any welders worth their salt will always perform a quality check of their work before completing it. This often involves checking their work under magnification from one or more angles. This helps to ensure that they have accurately created the desired weld. In addition to good welding, the welders at Steel Cracked Bikes make sure each weld is clocked in a way that ensures it will remain the same for the life of your bike.

Most welders will use different ground rods and “helping hands” to complete your frame’s welds. The length, diameter, and type of rods used will vary between welders.

The length of the rods is important, but what’s even more important is the metals used to create them.

b) How are Cracked aluminum bike Frames Welded?

Eventually, cracks can appear in an aluminum frame that’s been served for a long time. This is very difficult to deal with as it requires new welding of the cracked piece. This would be highly problematic for one’s bike because the process would require much time and energy for its new welding to be complete.

But, if you know this process and are skilled in welding aluminum frames, you can make these cracks disappear with your small hand. Certain tools would enable you to do this effectively and fairly quickly.

One must use a welding gun with a rod or copper wire. This is because it would bring the person who performs this job close to the metal part covered. The heat formed by this process would result in a fusion between the two pieces of aluminum that need repair. The heat would then cool very rapidly, causing it to solidify once again. This forms a stable chemical bond between both parts of aluminum.

The process is also made easier by the use of flux. This is also used in gold plating, performed by a goldsmith. Flux is filled with a powdered substance, such as silver or tin oxide. The powder has the capability of forming a type of metal bond with aluminum that needs welding.

If the goldsmith is unavailable, one can also use silver or tin oxide. These are used to weld aluminum. Besides this, a strong adhesive is also needed. This would keep the piece in place so it would not fall off during the welding process.

Aluminum Cracked bike Frames Welding is a process that requires you to be very careful and creative when performing the task. To ensure the welded place is strong enough, you must give it time to solidify. After the welding process, your work would help sustain the aluminum bike frame for a very long period.

c) How are Cracked carbon bike Frames Welded?

A carbon frame is a hard material composed mainly of high-density polyethylene (HDPE), with some carbon fiber and resin. Front forks and rear dropouts typically have bronze bushings to add resilience, while the steerer tube is often made from aluminum. Companies produce a cracked carbon bike frame by welding the piece in question back together with an arc welder. However, certain types of welding, such as flux-cored arc welding and gas tungsten arc welding (GTAW), produce a different result than conventional cathodic arc welding (CAW) due to their different method.

Cracked carbon frames exhibit a certain type of microstructure called “carbonization,” which is not much different than the microstructure found in poorly-machined steels. The carbonization process is carried out by heating the piece in question to its melting point, but it variously leads to cracks in a warped material. The crack formation depends on the cooling rate, accelerated by the weld quality and process.

Before welding any parts of a cracked frame, ensure that you have coated both parts with a flux that matches your carbon repair rod. The flux protects the carbon against impacting carbon fibers and makes welding easier. If you use an arc welder, ensure that you have a starter gun, electrode, and filler rod at hand. The filler rod is used before welding to prevent “burn-through.” It would help if you also bought a suitably sized piece of wire, which should be pressure-welded to eliminate “cold spotting.

How much does it cost to weld a cracked frame?

How much does welding a frame for a bike cost? The welding price might depend on the type of bike being repaired and its size and complexity. The price may even depend on the shop or the type of material being used for repair. A frame that is badly cracked along its length would cost more than one that was less severely damaged. The price may also depend on the shop’s reputation for welding repair. Using a local shop could save money, but you must weigh this factor against the opportunity cost of being away from home when the bike needs repair.

Also important to consider is whether you are repairing a bike for yourself or someone else. If you are repairing your bike, the costs will be a small fraction of those for another rider. The other rider’s bike may not be able to handle the same sort of repairs as yours, and so this factor can help guide prices.

You can do a few different things to get the lowest price for welding your frame. One thing that everyone should be aware of is the type of welding machine you are going to use. An arc welder is better at welding very thin metals, such as aluminum, while stick welders work better welding thicker materials, such as steel and cast iron.

Another way you can save on repairs is by buying an old frame or frame parts instead of paying an extra professional to weld it up for you. Check out the sites on Craigslist and eBay in your area to find a good buy. If you can’t find a used frame, check out the local salvage yards; they may have an old bike with parts you can use to repair it. However, there are many things to consider before buying a used frame.

Sometimes people will buy an old frame for $50 and insist on paying more for welding it up.

The first step in repairing a cracked frame is to weld it. Some people jump straight into that, but I advise against it because you don’t want a weak weld holding the pieces of your frame together any more than you already have.

The next step, which most people seem to skip, is to replace the tubes. This step is required because you need to remove the old tubes, which are now cracked and unsafe. If they’re not removed completely and replaced with new ones, a crack can run through any welds you’re about to make.

The third step is to do a few measured cuts on the frame so it can be sanded and polished. These cuts are also needed to restore the tubes and add them back into the frame.

This is where I find most people stop and make their mistakes. The last step is to re-weld your frame and Seatpost. The welds are so weak they can be easily broken off if you’re not careful. Remember that if you’re welding an item with duct tape or another adhesive, you’ll need to replace that first with new glue or a different material.

The total cost for this restoration was around $100. This excluded the tubes, around $40 per pair, and the Seatpost, around $13. These prices are purely estimates as I haven’t looked them up at my local bike shop.

I have provided a breakdown of every step regarding raw materials and the total dollars spent welding a cracked bike frame.

Why you should not buy a cracked bike

There are some good reasons why you should not buy a cracking bike. First, a crack will usually increase in length until it becomes larger. A buffed but unsmoothed crack will increase in length by several millimeters within a few rides. It is also possible that the crack will become deeper if you ride with a heavy bag on your shoulder!

This is because of the simple physics behind frame flexing. When flexing the frame downhill or being hit by a car, you are supported on the top of your bottom bracket, and your weight causes stress in both horizontal and vertical directions. An unsmoothed crack will increase in length, and because the crack is not smoothed, the edges of the crack will be sharper than if a diamond wheel were used.

The second reason not to buy a cracked bike is that the metal underneath can be damaged. A crack will stress much thinner metal parts, such as tubes, and stays. Parts that are stressed this way fail due to fatigue. A cracked frame can damage other parts, such as zip ties, brake cables, and brake lines.

A third reason to avoid a cracked bike is poor weld quality and semi-automatic welding. A good weld is smooth, without metal blobs on the weld’s surface. Furthermore, the edges of a good weld should be rounded, not sharp or squared off.

Semi-automatic frame welders are faster than hand-welding and have less skill required to make a passable frame.

The final (and most important reason) for avoiding cracked frames is that not all dealers fix their broken frames correctly. For example, the fix could be “prestressed” by excessive force applied to the seat tube or top tube in a perpendicular direction. Any frame flexing will cause this “prestress” failure to fail again.

If you ever find a bike shop that fixes cracked frames by welding them, inspect the welds closely before you buy them. Make sure the welds are smooth and not blobby, without sharp edges. Inspect the welds at several angles, including 45, 90, and 135 degrees. A good frame will be uniformly covered with stainless steel at each angle, and you should see no signs of impurities like carbon or plastic.

If you find a frame that looks ready to crack again, ask the shop owner if he can prove to you that a new frame will not fail again. The shop owner should be able to show you a similar frame that is still in use (not yet cracked). If the shop has no similar frames, do not buy the bike.

If you are interested in buying a used frame, ensure it has not been fixed by over-tightening. To accomplish this, look for evidence of “prestress” fracture on both the top and the down tubes. Look for cracks around rivet holes as well.

Conclusion:

The final words are that the cost to weld a cracked frame varies depending on many factors and cannot be fully determined without knowing specifics about an individual project.” But roughly, it can be said that $50 to $100 will be required to weld a cracked frame.